Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

Ever wonder how things like spoons and chairs, or even car parts are made from metal? Although this might seem commonplace, the journey from these items starts here. Custom Metal Stamping DieOne of those steps is metal stamping which uses a custom tool called the die for it. It is an important part of the manufacturing process for metallic items and guaranteeing their shape.

A Metal Stamping Die - Basically a Cookie Cutter It's like using a cookie cutter, you press it on the dough to give shape.breakpoints([],RequiredMixin) A metal stamping die is pressed down onto a piece of metal and shapes it into various forms. A big sheet, and some metal on it first. Afterwards, the die is pressed into the metal with a greater force. It shapes the metal because of that pressure. The applications for these methods are infinitely varied, from the production of auto parts to intricate metalwork and jewelry.

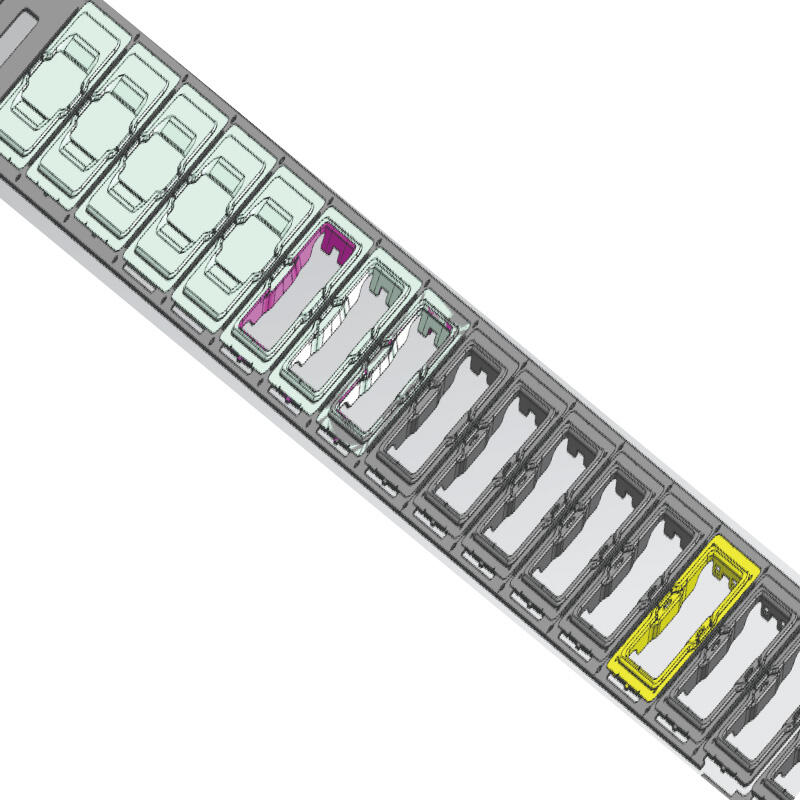

Different metal objects are not same, and for that reason we require personalized steel marking passes away. A specific shaped or custom die is used for a certain shape of product, ex: car door, metal charm and apart belonging to machine. When poured into the machine, it makes sure there is no gaps and thus help in forming the right shape by encircling around die.

Custom metal stamping dies are essential in manufacturing as they ensure that each and every object is consistent; looking right. For a part not designed for any particular product, end-metal parts may result in bad shape if none of the dice is prepared. One of the various examples is -Alright like if stamping doesnt come out perfect, a car door mite not fit well into the qcar. If assembled, the car will prove to be disastrous.

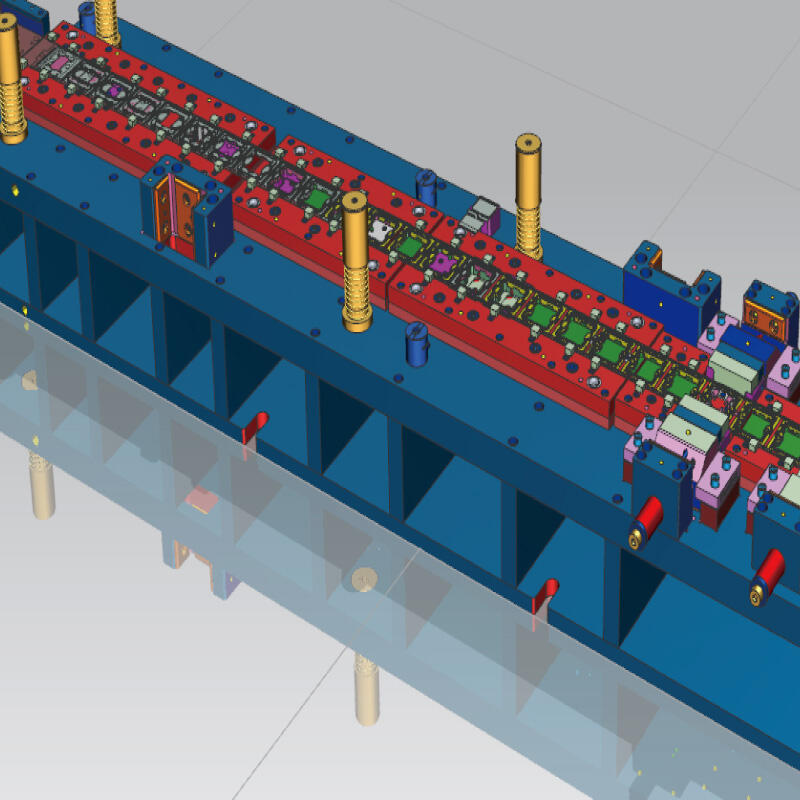

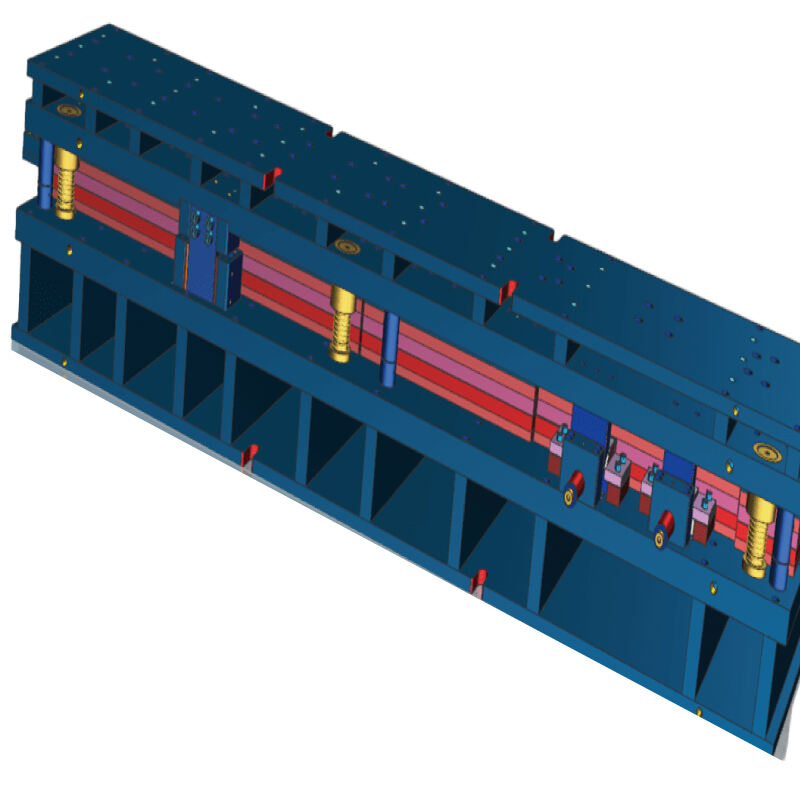

Forming a custom metal stamping die requires significant skill and knowledge. The whole thing begins with a Design Concept that is subsequently translated in to 3-Dimensional Model via special computer programs. This intermediate model is used to make an actual die. This version is used to verify that everything works as expected and shapes the metal properly.

Automated machinery can also work with custom metal stamping dies. This in turn is the power for everything else going faster, as machines can punch out loads of precisely fabricated metal items;quickly... and no arms are expected to do it by people which helps. They excel at high-speed repetitive tasks - they can produce more metal widgets in a day than humans ever could.

A very interesting development in my opinion is the production of prototype metal stamping dies on a 3D printer. This creates a faster working environment for the designers and gives them space to make changes before they have stronger dies. Designs can be iterated quickly, which has potential to save time and resources in design by 3D printing.

SHQD is a well-equipped testing lab and 40 QC/QA inspectors. Quality inspection of raw materials through semi-finished items to finished goods. As a certified company under the ISO9001, ISO14001 system, and UL standards, we have established an efficient quality control and management of the environment that can ensure that we have a strict control on the passing rate and defect rate. We offer high-quality metal as well as custom metal stamping die to our clients.

SHQD is a RD company with a professional team comprising 23 engineers and managers. Additionally, it holds more than 40 patents related to metal manufacturing and injection molding. By relying on the power of custom metal stamping die, we participate in front-end design and create new technology, new products, prototyping, testing and promotion. We are committed to providing tailored high-end solutions for the projects of our clients.

With a total of 24 years experience in the field of manufacturing, SHQD has become one of the biggest injection molding factories in custom metal stamping die and offers OEM/ODM service in both injection molding production as well as sheet metal fabrication. SHQD has more than 1,000 production equipment, and several production lines that are automated, as well as a single-stop shop for services ranging from mold design and tooling making to production, assembly, and logistics.

Our supply chain is seasoned and our custom metal stamping die team is professional We can lower the cost of raw materials and provide you with injection molding and sheet-metal fabrication services at a competitive price Our sales staff can assist you provide high-quality services by taking into account various factors such as quality cost and transport