Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

There are just as many benefits of custom stamping parts. To be Frank first off they are super structural and last quite long. They can withstand extreme heat, heavy weights and high pressure. They can last a long time, as they are very robust and do not wear out easily (as often is the case with delicate clothes that break or need repairing after short period of wearing) This durability along with many other good characteristics makes it a smart choice for may applications where reliability is important.

Custom stamping parts are strong and cost-effective. This makes them less costly to manufacture than alternative components that may be made using alternate processes. Due to the fact that they are produced from raw materials, production costs of custom stamping parts are lower. They can also be made in large numbers, which helps save resources as well as time. The companies that demand a lot of parts in very little time may be interested with this capacity to generate quickly.

Custom stamping part is highly relevant to manufacturers that must keep up with the pace in their industries. These parts are used to develop a different model of products, which differentiate manufacturers from competitor. That is do not have to ever worry about the limitations of a particular material, giving them complete are fought in defining their typefaces. On top of that, custom stamping parts enable manufacturers to develop tailored components which are designed only for particular fields or application forms so it will get their goods a lot more desirable.

In addition, using custom stamping parts can also lead to less waste as manufacturers utilize every possible piece of sheet metal. This means they are able to use less materials in their manufacturing processes, and not only is that cheaper for them but it is also better for the environment. Today, many companies want to reduce their environmental impact related with production. Additionally, time can be saved and efficiency improved by using machinery for stamping purposes.

Custom stamping parts are easy to create. That starts by creating a part CAD model (Computer-Aided Design) using design software. This software provides a comprehensive and accurate vision of the part permitting designers to prepare precise plans. After the design is finished, it goes to a stamping machine. This thing cuts the design in metal and a custom part comes out at the end.

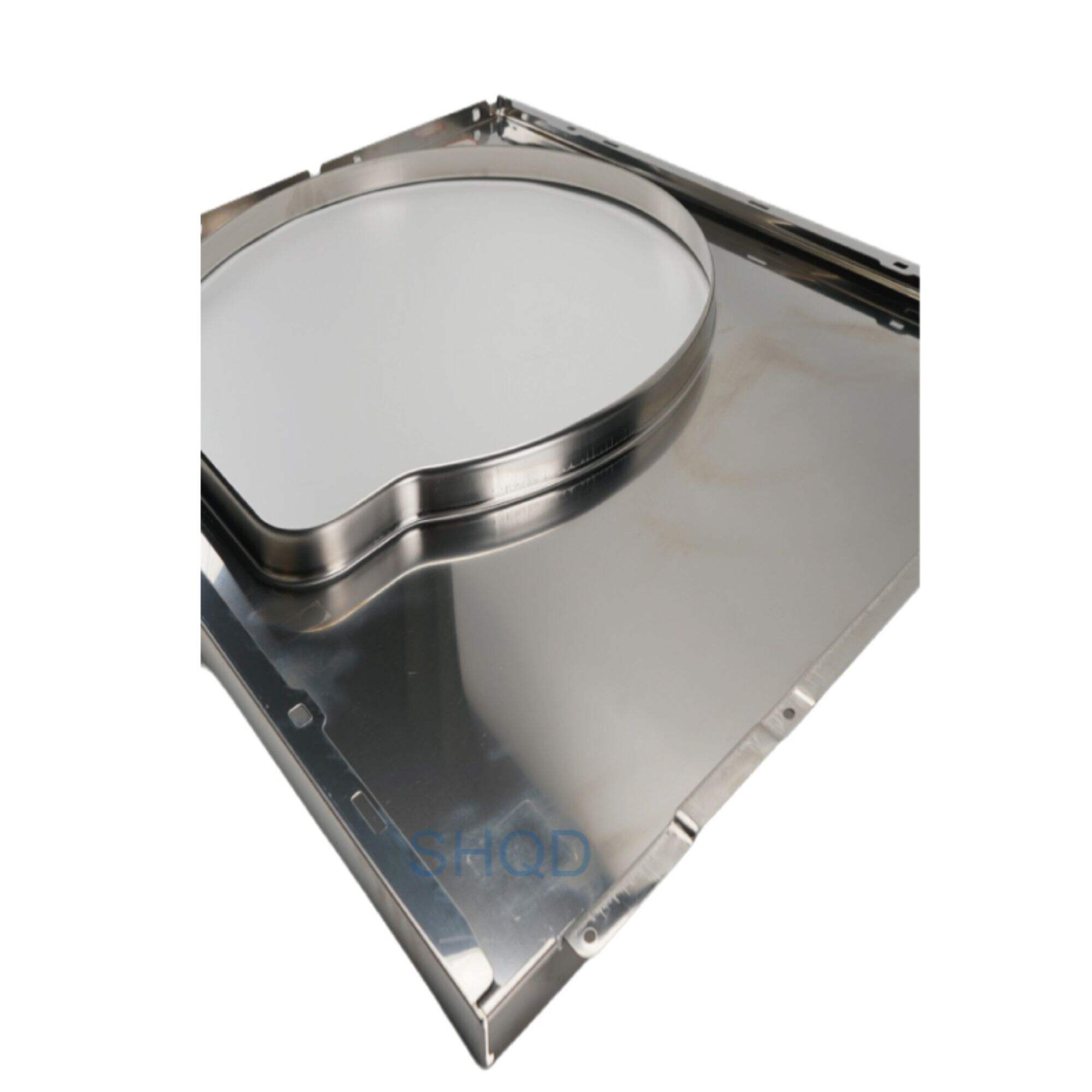

This way of creating parts is very efficient as it results in high-quality pieces directly to the design. Custom Stamping Part ManufacturersMaterials for custom stamping parts can also range widely, such as copper materials (yellow copper), aluminum materials, brass and stainless steel. Different applications require different properties of each material

Manufacturers can also look at new materials like high-strength steel and titanium. Theoretically, assemblies made out of these components would be both light and strong. Additionally, manufacturers can select from a range of finishes including powder coatings or electroplating to improve part aesthetics These were their attempts at reducing weight of the part, not enhancing it in terms of look and performance.

With 24 years of experience in custom stamping parts, SHQD has become one of the largest injection molding factories in China offering OEM/ODM services for both injection molding production and sheet metal fabrication. We own more than 1,000 production equipment and several production lines that are automated, and offer a one-stop service including tooling design and mold making to production, assembly and logistics.

SHQD is a professional RD team, 23 project and design engineers, and over 40 patents for custom stamping parts and injection molding manufacturing. We rely on our research and development efforts to take part in front-end design and to develop innovative technology, products and technologies for prototypes, tests, and marketing. We're committed in providing high-end custom solutions for our customers project.

custom stamping parts supply chain system is seasoned and our purchasing team is professional We can help you reduce the cost of raw materials and offer you injection molding and sheet-metal fabrication at reasonable prices Our sales team can help to provide top-quality services by taking into consideration various aspects including quality cost and transportation

SHQD has a highly custom stamping parts testing laboratory and 40 QC/QA inspectors, quality inspections from raw materials to semi-finished items to finished goods. As a certified company under the ISO9001, ISO14001 system, and UL standards We have developed an efficient quality control and management of the environment to ensure that we have a strict control on the pass rate and defect rate. To provide our clients with top-quality metal and plastic components.