Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

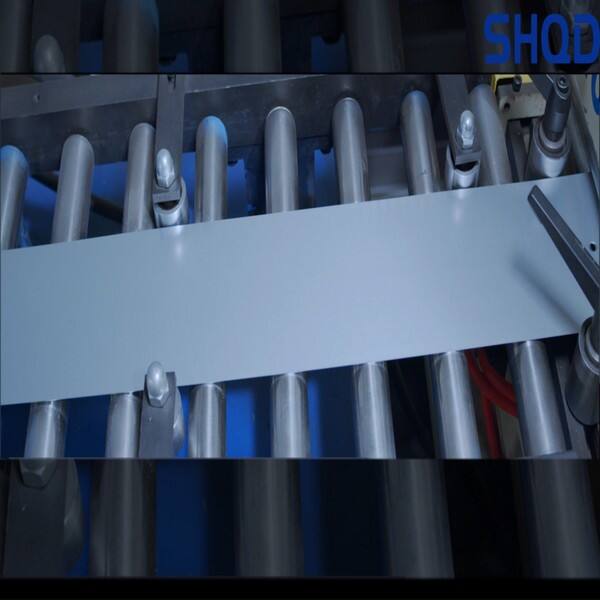

How different shapes are demolition in metal - have you ever thought of that? Shearing is the process of cutting sheet metal. It is cut to the shapes we require using a very accurate metal sheet cutting machine that can easily make cuts into any thickness of up to 25mm material. Qingdao Victory basic metal fabrication has a sharp blade used to cut through the metal. High-carbon s teel or tungsten carbide is used to make the blade which makes sure that it remains sharp and works efficiently. This blade cuts the steel sheet softly, when the blade is pressed to down on metal its give clean neat cut which required in many works.

Metal Shearing - Making Exact Shapes Every Time In A Number Of Jobs And Industries Particularly useful for shearing sheet stock like the flat stuff that becomes tools or car parts (and countless other things). Metal shearing is used to get the correct shape in size for a project that is being carried out and so by using this type of equipment, members who are working can do exactly what needs to be accomplished. Qingdao Victory air conditioning sheet metal shearing begins with a large metal sheet. The worker inserts the metal sheet into a box in which driven rollers create shape of tunnel. Next, they mark the exact measurement for desired cut and guide sheet through machine. The sharp blade comes down with enough force to cleanly sever the metal. Then it is cut in to the required shape and size after that

For example, if you manufacture metal products, and then one of the machined operations is shearing. With a metal shearing machine, you can obtain clean cuts and much less waste. This allows you to save time and money, that can be very beneficial for any business. This custom metal punch stamp also benefits happy customers, that receive the product exactly how it looked in the picture on your website.

You will be able to get the best possible cuts when you know more about how it works. In the event before anything else, basic metal fabrication is essential to use a right blade for the metal you are cutting. Certain blades are better suited to specific types of metal and different thicknesses, so do your research on the best one for whatever it is you are using them on.

One of the other things to consider is how fast is that blade moving when cutting through metal. If it goes too slow, the blade gets dull (or starts to break you do not want that) However, if the blade runs too quickly, a nasty cut can result as well and that spells trouble. Qingdao Victory custom metal stampings is important to find the right speed so that the slices are clean and precise.

SHQD is a well-equipped testing lab and 40 QC/QA inspectors. Quality inspection of raw materials through semi-finished items to finished goods. As a certified company under the ISO9001, ISO14001 system, and UL standards, we have established an efficient quality control and management of the environment that can ensure that we have a strict control on the passing rate and defect rate. We offer high-quality metal as well as Metal shearing to our clients.

We have a mature supply chain system and an experienced purchasing team which will help you Metal shearing the cost of raw material purchasing and offer a cost-effective injection molding and sheet metal fabrication services Our sales representatives will assist you provide top-quality services taking into consideration various factors like cost quality and transportation

SHQD with over 24 years experience in manufacturing, has grown to be one of the largest Chinese injection molding companies. We offer Metal shearing services for sheet metal fabrication and injection molding. We have more than 1,000 production equipment and numerous automated production lines and provide one-stop services from tooling design and mold manufacturing to assembly, production, and logistics.

Metal shearing is a professional RD team, 23 design and project engineers, and more than 40 patents related to metal fabrication processing and injection molding production. With the help of research and development, we are involved in front-end design and make new technological, innovative prototypes for products, testing and promotion. We're committed in providing high-end personalized solutions for our clients with their projects.