Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

Ever wonder how your favorite toys, gadgets or even cars are made? The process that deals in all of this is known as metal fabrication. Metal fabrication is the process of cutting, bending and shaping metal in a way that makes it useful or desirable. This process is significant because it results in the production of many daily-life used objects.

We do it with prototype metal fabrication. This is done to simulate a model or the other version for testing before making all of the final product. Its like how you get to do a first draft before writing the final history. This enables an engineer, or designer to identify and correct any potential issues with their design before mass production. During manufacturing, it saves time + money – this is critical in the world of making stuff.

Inescapable, things need time to make with and time in factories is a very precious resource. Manufacturers can massively produce the same items simultaneously by using prototype metal fabrication so that it will cut time and cost for their production. That means they can move the products into stores sooner, which makes customers happy.

Precision metal fabrication creates the tight tolerances needed to build parts with close-fits that work in harmony. To bring you this state of Type X automatics lab extruder with economical scientific instruments in the fastest possible time, we insist on standardization. This standardization ensures that the final products are reliable and work as intended, which keeps customers happy with their purchase.

The process of prototype metal fabrication takes an idea and turns it into something that can be created for everyday use. Prototyping is the backbone of all designer and engineering workflows, without which their ideas would have no head or feet to test anything on. Think of it like an architectural scale model: the building is not yet in its final location, but you can get a feel for how it would look when built. It is in this process, where design starts taking shape and more ideas or improvements start pouring.

Realizing real products from ideas is something that has allowed the manufacturing industry to make things benefitting our lives in many different ways. Whether by creating toys that inspire and bring smiles to kids or making medical equipment stand up under stress long enough for doctors to save lives, prototype metal fabrication is an important part of building products capable of changing the world we live in.

Metal Fabrication Prototyping Is Essential for the Success of Manufacturing and High Quality It allows manufacturers to locate deficiencies in their designs and subsequently fix any issues without making thousands of un-sellable products. Efficiency and reliability are crucial here, as they require greater precision (and more speed for technology or health segments).

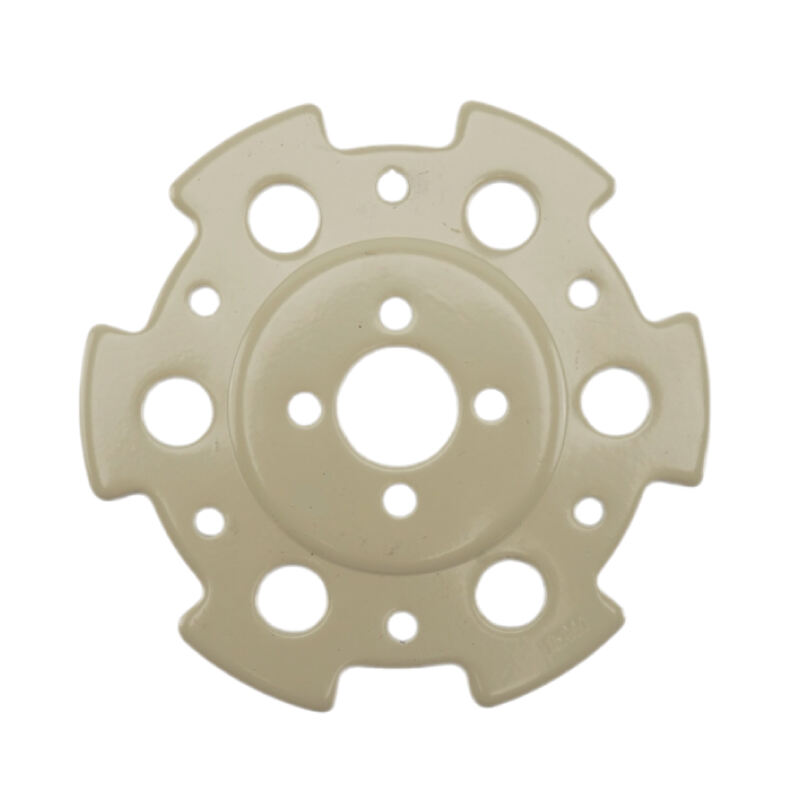

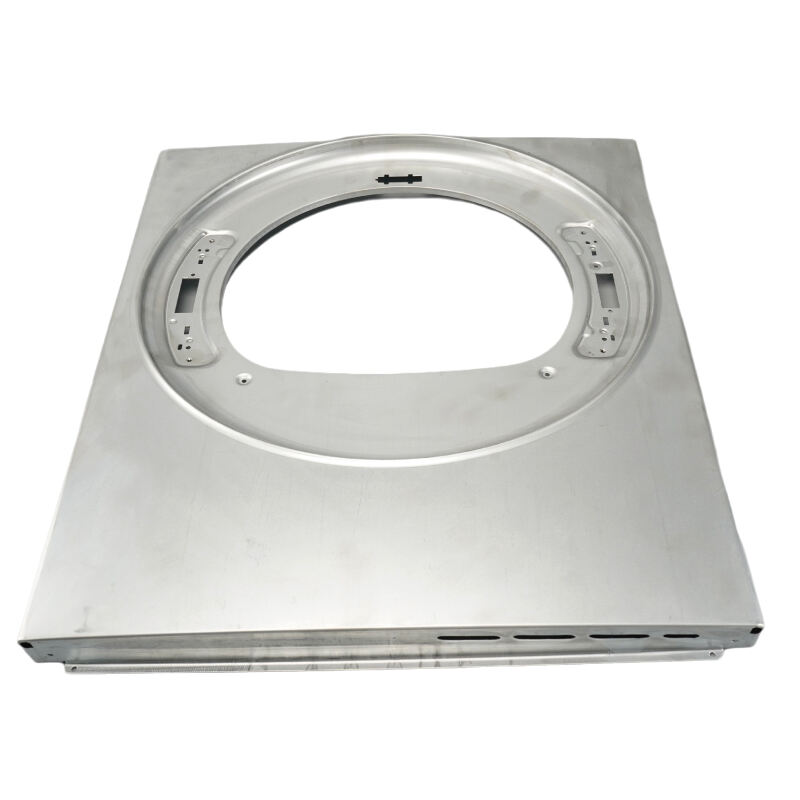

prototype metal fabrication With over 24 years of experience in manufacturing, has grown to be one of China's biggest injection molding companies. They offer OEM/ODM service for sheet metal fabrication and injection molding. SHQD owns more than 1000 production equipment and automated production lines. We provide a complete service that includes tooling design, production, mold making of the assembly line, and logistics.

We have a prototype metal fabrication supply chain system and an experienced purchasing team that can assist you in reducing the cost of purchasing raw materials and offer affordable injection molding as well as sheet metal fabrication Our sales team will help you to offer high-quality service by considering various aspects like cost as well as quality and transportation

SHQD has a highly prototype metal fabrication testing laboratory and 40 QC/QA inspectors, quality inspections from raw materials to semi-finished items to finished goods. As a certified company under the ISO9001, ISO14001 system, and UL standards We have developed an efficient quality control and management of the environment to ensure that we have a strict control on the pass rate and defect rate. To provide our clients with top-quality metal and plastic components.

SHQD is a professional RD team, 23 prototype metal fabrication and design engineers, and over 40 patents related to metal processing of fabrication and injection molding production. We rely on our research and development to contribute to front-end design and to develop innovative technologies, new products prototyping, tests, and marketing. We're committed to providing high-end custom solutions for our customers and their projects.